Better Processes for all.

Process Reference Models - Industry Best Practices - On Demand

LEARN MORE ABOUT BUSINESS FLOWS >

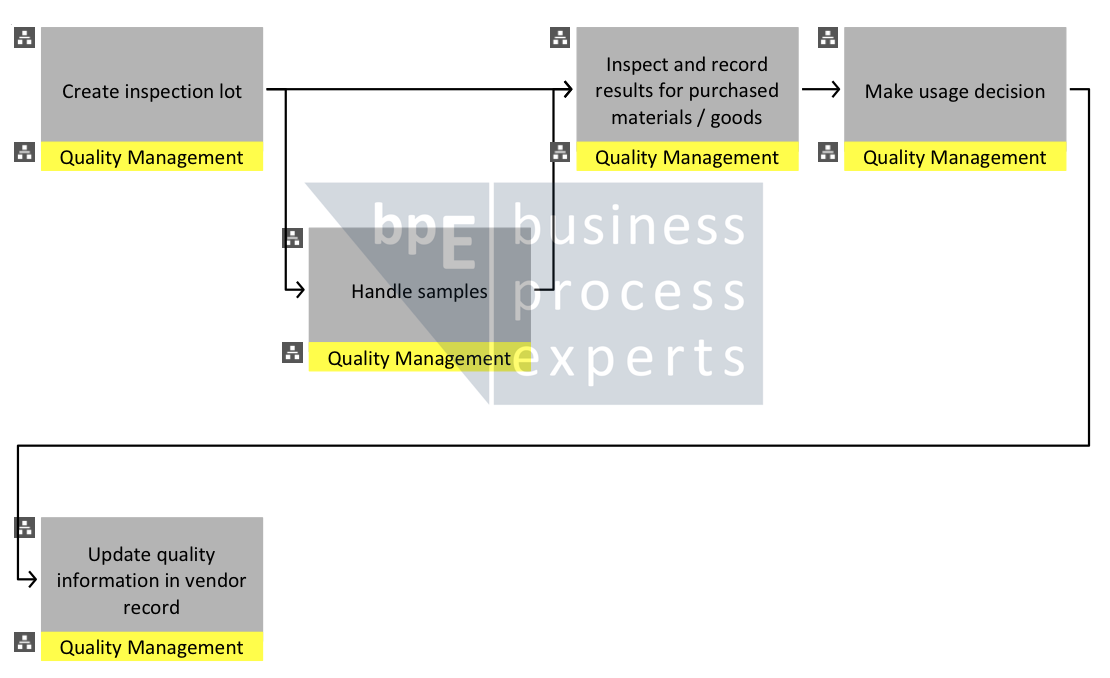

Inspect to Quality > Inbound inspection

Scenario Description

The Inbound Inspection scenario covers the process flow to control the quality of incoming goods and materials before further processing. The control ensures that the delivered good or material complies with the specification agreed with the supplier. The process can also cover only inspection of required certificates etc. - not inspection of goods themselves. (e.g. in drop shipment scenarios).

End-to-End Process Flow

Click on the example "Make usage decision" to see more details.

Process Descriptions

Create inspection lot - Quality inspections are processes on the basis of inspection lots. If a specific quantity of a material is inspected, an inspection lot must be created in the system.

Handle samples - Handle samples process provides information on the collection and extraction of samples.

Inspect and record results for purchased materials / goods - Samples (sample may refer also to a 100% inspection) get inspected for each inspection characteristic. The results are recorded. Basis for the inspection are the internal goods specification and the vendor goods specification. The recorded inspection results document the quality of the inspected product, which might include quality related documents and certificates provided by the vendor.

Make usage decision - Based on the documented results of the quality inspection, a decision on usage and final quality is made by an authorized and qualified person. It specifies whether the goods in the inspection lot have been accepted for use or rejected.

Update quality information in vendor record - After quality results of all inbound goods are defined and tracked, the information regarding the vendor shall be updated to ensure a constant quality for the delivered products or goods.